Corner Tube Boiler Series

Single-drum, natural-circulation corner tube boilers designed for high-efficiency power generation, industrial steam, and cogeneration projects. Compact layout, fast erection, and stable long-term operation.

Corner Tube Boiler Question Tank

Targeted answers to the most common questions from EPC contractors, IPP developers, and industrial steam users considering corner tube boiler technology.

1. What is a corner tube boiler and where is it used?

A corner tube boiler is a single-drum natural circulation boiler where the drum is supported by rigid downcomers located at the four corners. The membrane water-wall furnace, convection shaft and heating surfaces are hung from this frame, forming a compact, fully enclosed structure. It is widely used in:

- • Coal-fired and biomass power plants

- • Industrial cogeneration units for sugar, paper, and chemical plants

- • District heating and captive power projects

2. What are the main advantages of a corner tube design?

Compared with conventional two-drum or tower-type boilers, corner tube boilers offer:

- • Compact layout: small footprint and simple steel structure supported at the corners.

- • Good circulation: downcomers and risers arranged for reliable natural circulation and low risk of vapor blanketing.

- • High gas tightness: membrane walls provide good furnace sealing and low air leakage.

- • Fast erection: many modules can be prefabricated in the workshop to shorten on-site installation time.

3. What fuels can ORL corner tube boilers use?

The specific fuel range depends on furnace cross-section, bed temperature and combustion system, which are all customized based on your fuel analysis. Typical fuels include:

- • Bituminous and sub-bituminous coal

- • Lignite and blended coal

- • Biomass and agricultural residues (with appropriate fuel system)

- • Industrial by-product fuels after technical review

Final fuel range and performance are confirmed during detailed engineering.

4. How is boiler efficiency and load response improved?

Corner tube boilers from ORL Power are designed with:

- • Membrane water walls and optimized flue-gas path to reduce heat loss and improve heat transfer.

- • Economizer and air preheater matched to the actual flue-gas temperature profile.

- • Proper furnace height and convection surface arrangement for stable combustion and good part-load performance.

- • Rational primary / secondary air ratios to reduce auxiliary power consumption.

Target efficiency and guarantees are decided according to your fuel, auxiliaries and contract scope.

5. What is typically included in the corner tube boiler supply?

Supply scope is flexible and can be adapted to EPC or owner requirements. A typical boiler island package includes:

- • Furnace, convection shaft, steam drum, headers and downcomers

- • Superheater, reheater, economizer and air preheater

- • Complete membrane water-wall system and gas-tight casing

- • Corner-supported boiler steel structure, stairways and platforms

- • Valves, expansion joints and on-line cleaning devices as specified

6. What information is needed to start a corner tube boiler proposal?

To prepare a technical scheme and budgetary offer we recommend sending:

- • Required steam capacity / power output, pressure and temperature

- • Fuel analysis (proximate / ultimate, LHV, ash & sulfur)

- • Expected operating mode and annual running hours

- • Local emission limits and preferred flue-gas cleaning system

- • Site conditions (altitude, cooling water, ambient temperature)

You can paste this data directly into the inquiry form below, or attach it as a document when you contact our team.

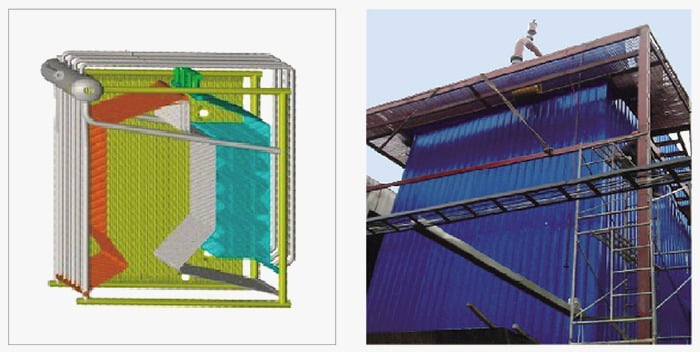

Corner Tube Boiler Design Highlights

ORL corner tube boilers are developed based on power plant practice and industrial experience. The structure is designed for long service life, stable circulation, and convenient installation.

- • Four-corner downcomer support: drum and heating surfaces form an integrated frame with good stiffness and low thermal stress.

- • Full membrane water-wall furnace: reduces refractory, improves sealing, and helps control furnace wall temperature.

- • Optimized steel structure: calculated with boiler design software to ensure safe load distribution under all operation and wind load conditions.

- • Modular prefabrication: large sections can be assembled in the workshop, reducing on-site welding and erection workload.

- • Flexible connection to balance-of-plant: steam piping, attemperation, and feed-water systems are matched to your existing or new plant layout.

Typical Application Scenarios

- • Coal-fired captive power plants

- • Sugar mill cogeneration units

- • Paper & pulp industry boilers

- • Chemical & petrochemical plants

- • District heating & hot water supply

- • Industrial process steam systems

- • Upgrades of aging boiler islands

- • New greenfield power projects

For brownfield projects, our engineering team can study your existing turbine, auxiliaries and civil work to recommend a compatible corner tube boiler solution.

Request a Corner Tube Boiler Proposal

Send us your basic project information and our engineering & commercial team will prepare a tailored corner tube boiler solution for your plant.

Helpful Details to Share

- • Steam capacity and main steam parameters you require

- • Primary fuel and any backup fuels

- • New plant or retrofit, and project location

- • Expected operating hours per year

- • Any special standards or owner specifications