Industrial Boiler Economizer

High-Efficiency Heat Recovery Solutions Engineered for Maximum Performance and ROI

What is a Boiler Economizer?

A heat recovery device that captures waste heat from flue gases to preheat boiler feedwater, significantly improving overall efficiency

Key Efficiency Rule

For every 40°F increase in feedwater temperature, boiler efficiency improves by approximately 1%

How It Works

Flue Gas Enters

Hot exhaust gases exit the boiler at 300-600°F

Heat Transfer

Gases flow through economizer tubes containing feedwater

Water Preheating

Feedwater temperature increases by 100-300°F

Energy Recovery

Cooled gases exit, preheated water enters boiler

Reduce Fuel Costs

Save 5-10% on annual fuel expenses

Boost Efficiency

Increase overall boiler efficiency by 3-5%

Lower Emissions

Reduce CO₂ and NOx emissions significantly

Fast ROI

Typical payback period of 12-24 months

Economizer Types Comparison

Choose the right economizer design for your specific application and fuel type

| Feature | Steel Tube | Finned Tube | Cast Iron |

|---|---|---|---|

| Heat Transfer | Standard | High (2-3x) | Moderate |

| Fouling Resistance | Excellent | Poor | Good |

| Footprint | Larger | Compact | Large |

| Price | Medium | High | Low |

| Maintenance | Easy | Difficult | Easy |

Steel Tube Economizer (Bare Tube)

✓ Advantages

- → Superior cleanability - ideal for dirty fuels (coal, biomass, heavy oil)

- → Simple maintenance with standard tube cleaning equipment

- → Proven reliability in harsh industrial environments

- → Wide range of tube materials available

- → Lower initial cost compared to finned designs

- → Easy inspection and tube replacement

▸ Best Applications

- • Coal-fired boilers with high ash content

- • Biomass and waste fuel applications

- • Heavy oil-fired industrial boilers

- • High-temperature exhaust applications (>800°F)

"Steel tube economizers are our most popular choice for industrial clients requiring robust, low-maintenance solutions for dirty fuel applications."

Finned Tube Economizer

Available in Spiral Finned and H-Type configurations

✓ Advantages

- → Compact design - 50-70% smaller footprint

- → 2-3x higher heat transfer efficiency

- → Ideal for clean fuel applications (natural gas, light oil)

- → Lower installation cost due to reduced size

- → Better for retrofit projects with space constraints

✗ Disadvantages

- • Difficult to clean - fins trap ash and deposits

- • Not suitable for dirty or high-ash fuels

- • Higher maintenance requirements

▸ Best Applications

- • Natural gas-fired boilers

- • Light oil applications with low sulfur content

- • Space-limited retrofit installations

- • Low-temperature exhaust (<600°F)

Cast Iron Economizer

Traditional design primarily used in older installations. Features modular cast iron sections that can be assembled on-site. While durable and corrosion-resistant, they are largely being replaced by steel tube designs due to better performance and lower cost.

Limited Applications:

Replacement parts for existing systems, some commercial heating applications

Market Trend:

Declining usage due to better alternatives

Not Sure Which Type is Right for You?

Our engineering team will help you select the optimal design based on your fuel type, space, and budget

Materials & Standards

International compliance and quality assurance for global deployment

Certifications & Standards

-scaled.jpg)

Material Selection Guide

| Application | Temperature Range | Fuel Type | Recommended Material |

|---|---|---|---|

| Natural Gas Boilers | 300-600°F | Clean fuel | Carbon Steel SA-210 Gr.A1 |

| Oil-Fired (Low S) | 400-700°F | Light oil <0.5% S | Carbon Steel SA-210 Gr.C |

| Coal/Heavy Oil | 500-800°F | High sulfur content | Low Alloy Steel SA-213 T11/T22 |

| Biomass/Waste | 400-700°F | Corrosive conditions | Stainless Steel SA-213 TP304/316 |

| High Temperature | >750°F | Various | Alloy Steel SA-213 T91/T92 |

Engineering Support: Our team will help you select the optimal material based on your specific operating conditions, fuel type, and budget requirements.

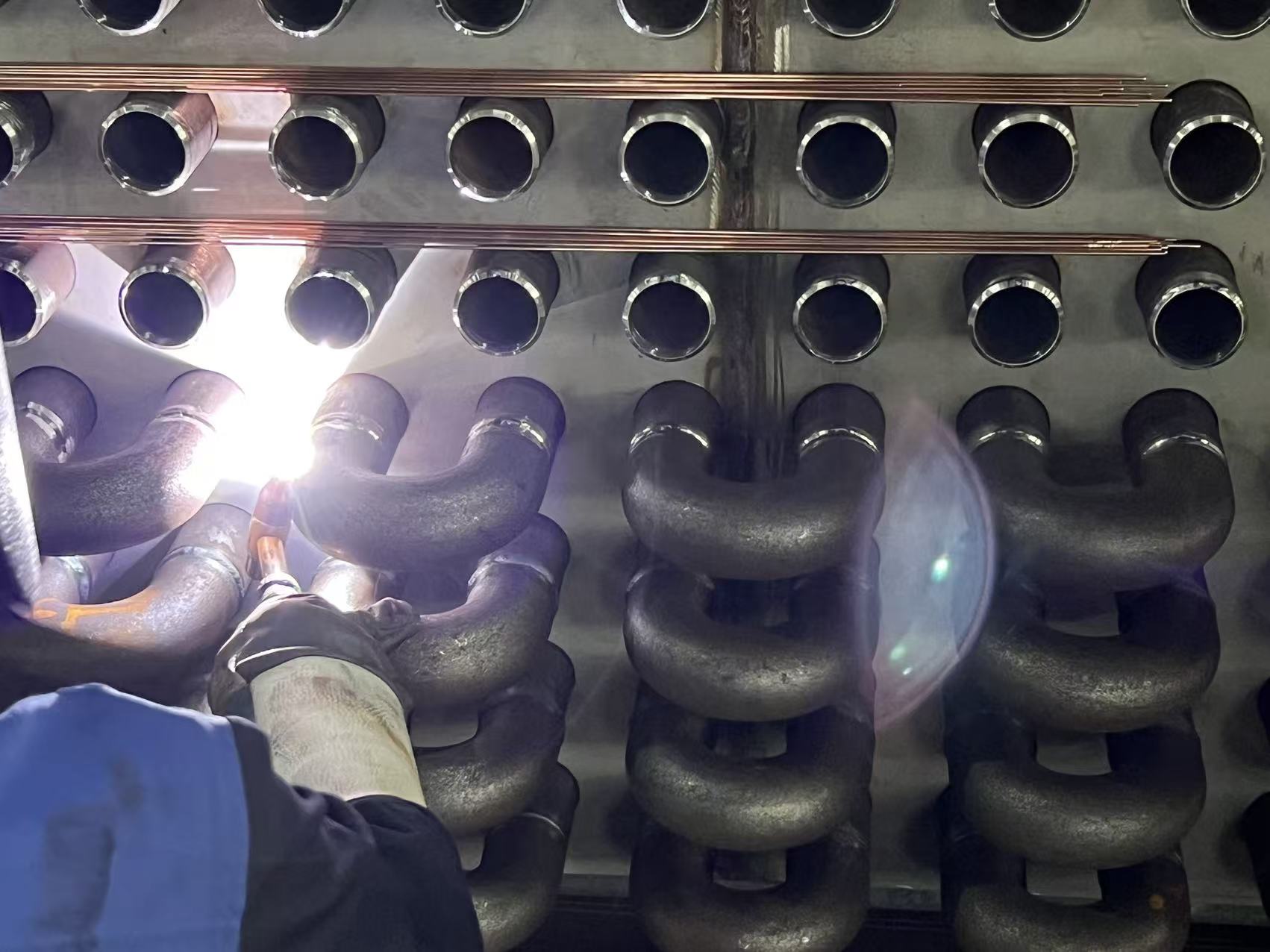

From Design to Delivery – One Supplier, Full Process Control

Complete manufacturing control ensures quality, efficiency, and on-time delivery for every project.

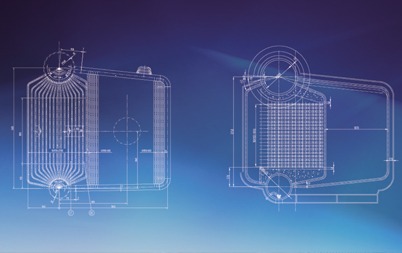

Engineering & Design

Technical Review & Performance Optimization

Our engineering team reviews your drawings and boiler operating data. We optimize tube layout, fin geometry, and material grade to maximize heat recovery efficiency and service life.

Request Engineering Review

Manufacturing

Quality Inspection

Each economizer is 100% inspected before shipment:

Surface Treatment & Protection

Shot blasting / descaling, anti-corrosion coating, and export-grade packaging keep your economizer protected from workshop to boiler house, ready for installation on arrival.

Shipping & Delivery

Our Shanghai area location provides fast access to major international ports. We prepare customs documentation, arrange sea or air freight, and offer flexible packing options (wooden crates, steel frames, or nude bundles) based on your site requirements.

Complete Process Control = Guaranteed Results

From initial design review to final delivery, our integrated manufacturing process ensures every economizer meets your exact specifications and performance requirements.

Industries We Serve

Trusted by leading companies across diverse industrial sectors worldwide

Power Generation

Utility & industrial power plants

Chemical Processing

Refineries & petrochemical plants

Food & Beverage

Processing facilities

Textile Mills

Steam generation systems

Paper & Pulp

Recovery boilers

Pharmaceutical

Clean steam applications

District Heating

Municipal heating systems

Waste-to-Energy

Incineration plants

Client Success Stories

"The economizer installation reduced our fuel consumption by 8% within the first year. Excellent quality and professional support."

Major Power Plant, South America

Power Generation

"Outstanding engineering support throughout the project. The custom design perfectly matched our retrofit requirements."

Chemical Facility, Middle East

Chemical Processing

"Impressive build quality and fast delivery. The payback period was even shorter than projected."

Food Processing, Southeast Asia

Food & Beverage

Join Hundreds of Satisfied Customers

Discover how our economizers have helped businesses like yours achieve significant energy savings

Why Invest in an Economizer?

Discover the compelling reasons why economizers are essential for modern industrial operations

Immediate Financial Impact

-

✓

Significant Fuel Savings: Reduces fuel consumption by recovering waste heat that would otherwise be lost

-

✓

Fast Payback Period: Most installations recover investment within 1-3 years through energy savings

-

✓

Long Service Life: 20+ years of operational life with proper maintenance

-

✓

Minimal Maintenance: Low ongoing costs with simple periodic cleaning and inspection

-

✓

Future-Proof Investment: Protection against rising fuel costs and energy price volatility

Operational Excellence

-

✓

Improved Plant Efficiency: Increases overall boiler system efficiency by 3-5%

-

✓

Environmental Compliance: Reduces CO₂ emissions by 15-25%, helping meet regulatory requirements

-

✓

Enhanced Boiler Performance: Preheated feedwater reduces thermal stress and extends boiler life

-

✓

Sustainable Operations: Demonstrates corporate environmental responsibility and ESG commitment

-

✓

Competitive Advantage: Lower operating costs improve market competitiveness

Key Investment Facts

Typical Fuel

Savings

Years Payback

Period

Years Service

Life

Achievable

Efficiency

Real-World Success Stories

Fuel Reduction Achieved

350MW power plant in South America reduced annual fuel costs significantly with our economizer installation

Investment Recovered

Chemical facility in Middle East achieved full payback in just 14 months through consistent energy savings

Efficiency Gained

Textile mill increased overall boiler efficiency by 3.5%, exceeding projected performance targets

Want to Know Your Exact Savings Potential?

Every facility is unique. Our engineers will calculate customized savings potential based on your specific fuel type, operating hours, current efficiency, and local fuel costs.

No cost, no obligation — just honest analysis from experienced engineers

Frequently Asked Questions

Quick answers to common questions about economizers and our services

What is the typical lead time for a custom economizer? +

Standard lead time is 8-12 weeks from order confirmation, depending on size and complexity. Rush orders can be accommodated with 6-8 weeks delivery. We provide detailed production schedules and regular updates throughout manufacturing.

Can you design economizers for retrofit applications? +

Yes! We specialize in retrofit projects. Our engineering team will work with your existing boiler drawings and site constraints to design an optimized economizer that fits your space limitations and connects seamlessly to your current system.

Which standards do your economizers comply with? +

We manufacture to ASME Section I & VIII, GB/T Chinese standards, and EN 12952/12953 European standards. All units are pressure tested and come with full documentation including U-stamp certification (when required).

Do you provide installation support? +

Yes, we offer complete installation support including detailed installation drawings, on-site supervision (if needed), commissioning assistance, and operator training. Our team can travel internationally to support your project.

What is the expected ROI and payback period? +

Most economizer installations achieve 5-10% fuel savings, resulting in payback periods of 12-24 months depending on fuel costs and operating hours. We provide detailed ROI calculations based on your specific operating parameters.

What maintenance is required for economizers? +

Economizers require periodic tube cleaning (frequency depends on fuel type), annual inspection of tubes and headers, and monitoring of pressure drop. We provide comprehensive maintenance manuals and can supply original spare parts.

Can economizers handle high ash content fuels? +

Yes! Steel tube economizers are specifically designed for dirty fuels including coal, biomass, and heavy oil. We incorporate features like wide tube spacing, soot blowers, and erosion-resistant materials for these applications.

What warranty do you provide? +

We provide 12-month warranty from commissioning date (or 18 months from shipment date, whichever comes first) covering materials and workmanship. Extended warranties are available upon request.

Get Your Custom Quote

Fill out the form below and receive a detailed proposal within 24 hours

Complete Boiler Solutions

Comprehensive range of pressure parts and complete boiler systems engineered for industrial excellence

Need a Complete Boiler Solution?

We deliver comprehensive engineering, procurement, and manufacturing services for complete boiler systems