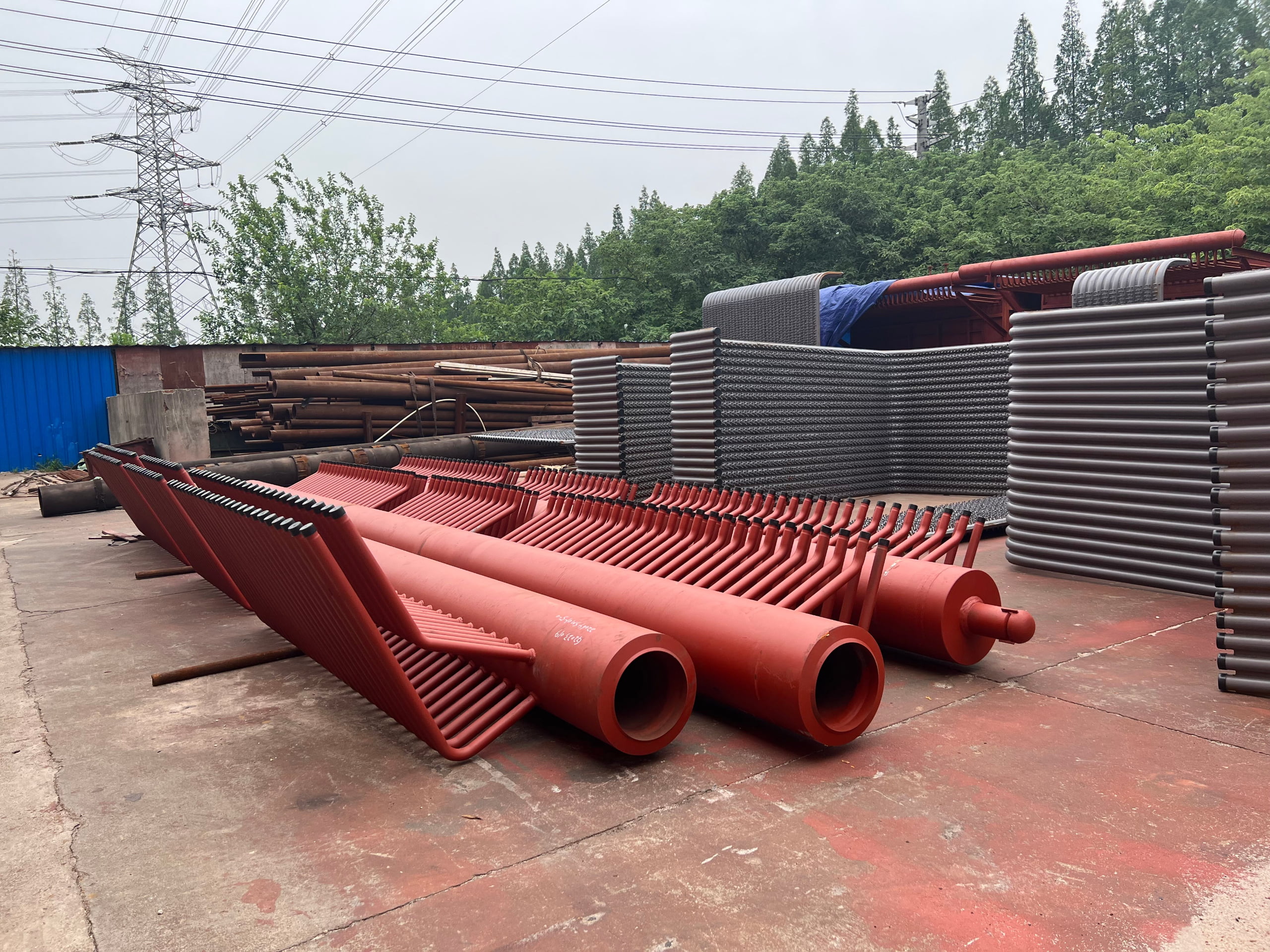

Boiler headers are cylindrical pressure parts that collect, mix and redistribute water or steam between different tube banks in a boiler. They act as critical junction points where multiple tubes are connected, ensuring proper flow distribution and pressure control across the boiler circuit.

Typical Header Positions:

- • Water wall inlet / outlet headers

- • Economizer inlet / outlet headers

- • Superheater and reheater inlet / outlet headers

- • Downcomer and circulation headers

- • Special distribution manifolds for industrial steam systems