CFB Boiler Systems

High-efficiency circulating fluidized bed (CFB) boilers engineered for power plants, captive power, and industrial steam users. Flexible fuel, low emissions, and stable operation for long-term, baseload service.

*Final performance and guarantees are confirmed during detailed engineering and contract stage.

CFB Boiler Question Tank

A dedicated CFB boiler knowledge page for EPC contractors, IPP developers, and industrial end users. Here we answer the high-intent questions buyers ask most often before issuing a technical inquiry.

1. What is a CFB boiler and when should I choose it?

A circulating fluidized bed (CFB) boiler suspends fuel and bed material in an upward flow of air, creating intense mixing and uniform furnace temperature. Compared with pulverized-coal boilers, CFB technology offers higher fuel flexibility, better part-load performance, and in-furnace desulfurization. It is ideal for:

- • Power plants using low-grade coal, lignite, petroleum coke, or biomass blends

- • Industrial plants (sugar, paper, chemical, metallurgy) with own solid waste fuel

- • Waste-to-energy and heat-and-power projects requiring stable long-term operation

2. What fuels can ORL CFB boilers burn?

We design each CFB boiler around the actual fuel analysis of your project. Typical fuels include:

- • Bituminous / sub-bituminous coal

- • Lignite, gangue, coal slime

- • Petroleum coke

- • Bagasse and biomass residue

- • Paper mill sludge, RDF

- • Industrial process by-products

For multi-fuel projects, our engineers adjust bed temperature, air distribution, and furnace cross-section to keep combustion stable across different fuel mixes.

3. How do you achieve high boiler efficiency?

Based on our reference projects, CFB boiler efficiency can be designed up to around 90% (LHV basis) when matched with proper auxiliaries. Our design focuses on:

- • Efficient separators: steel-plate adiabatic cyclone separator and steam-cooled volute cyclone for high solid recycling and low dust loss.

- • Optimized heating surfaces: membrane water walls, superheater, reheater, economizer and air preheater arranged for maximum heat recovery.

- • Primary / secondary air ratio: carefully tuned to reduce auxiliary power and improve burnout of unburned carbon.

- • Tall furnace design: long flue-gas residence time and large circulation rate, improving burnout while lowering water-wall heat load.

Final guarantee figures are confirmed by detailed thermal calculation and commercial contract.

4. How are emissions (SO2, NOx, dust) controlled in your CFB design?

CFB technology naturally operates at lower combustion temperatures, which already reduces thermal NOx. On this basis, we provide:

- • In-furnace limestone injection for SO2 capture

- • Optimized air staging and staged combustion for low NOx

- • High-efficiency cyclone separators to capture and recycle solids

- • Optional bag filter / ESP at the tail flue-gas section to meet local emission limits

Emission guarantees are based on your fuel sulfur / ash content and the final flue-gas cleaning configuration.

5. What is included in a typical CFB boiler supply scope?

Depending on your project and EPC split of work, ORL Power can provide pressure parts only or a more complete boiler island. Typical scope:

- • Furnace water-wall panels, superheater, reheater, economizer, air preheater

- • Steel-plate adiabatic cyclone separator and return-leg system

- • Steam drum, headers, downcomers, connecting piping

- • Boiler steel structure and platforms designed using professional boiler design software

- • Expansion joints, soot-blowers, valves, and on-line cleaning devices as specified

6. What information do you need to prepare a CFB boiler proposal?

To respond quickly with a technical scheme and budget price, please share:

- • Desired steam capacity, pressure and temperature (or power output)

- • Fuel analysis (proximate / ultimate, LHV, ash and sulfur contents)

- • Site conditions: altitude, cooling water source, local emission limits

- • Expected operating mode: baseload / peaking, annual running hours

- • Preferred design codes (ASME / EN / GB) and any owner standards

You can paste this information directly into the inquiry form below or attach it to your RFQ email.

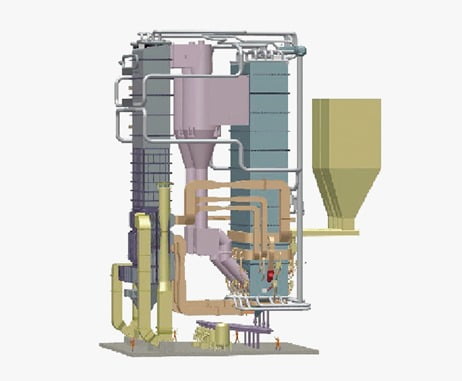

Core Design Features

Our CFB boiler series is developed from long-term operating experience in power plants, sugar mills and industrial facilities. The design focuses on reliable operation, uniform furnace temperature, and simple maintenance.

- • Efficient cyclone system: steel-plate adiabatic separators and steam-cooled volute cyclones for high solids separation efficiency and reduced wear.

- • Protected lower furnace: steam- or water-cooled cladding walls in the lower superheater and economizer zones to resist erosion and keep good gas tightness.

- • Optimized steel structure: calculated by professional boiler design software to ensure reasonable load distribution and safe operation under all load cases.

- • Rational air system: carefully designed primary, secondary and tertiary air grids to reduce fan power, enhance bed mixing, and improve combustion.

- • Tall furnace with large circulation: long flue-gas residence time and strong solids recirculation, increasing burnout and reducing the heat load on water-walls.

Typical Application Fields

- • Coal-fired power plants

- • Captive power for steel & metallurgy

- • Sugar mills & biomass power

- • Paper & pulp industry

- • Chemical & petrochemical plants

- • Municipal / industrial solid waste

- • Cement and building materials

- • Other solid-fuel energy projects

For brownfield retrofits or boiler upgrades, we can also match new CFB boilers with existing steam turbines and balance-of-plant systems after technical review.

Request Your CFB Boiler Proposal

Share your basic project data and our engineering & commercial team will prepare a tailored CFB boiler solution. Normally we respond within one working day.

What to Include in Your Message

- • Steam capacity / power output you require

- • Steam pressure & temperature (or process conditions)

- • Main fuel and alternative fuels with basic analysis

- • New plant or retrofit, country / region of installation

- • Expected start-up schedule and any special requirements