Boiler Air Preheater (APH)

Heat Recovery for CFB & Industrial Boilers

ORL designs and manufactures shell & tube air preheaters to recover waste heat from flue gas and preheat combustion air, helping you reduce fuel consumption and improve overall boiler efficiency.

Air Preheater Types We Supply

We focus on shell & tube type boiler air preheaters, suitable for CFB, biomass, waste incineration and industrial steam boilers.

Standard Tubular APH

Carbon-steel tubes for clean or moderate flue gas conditions. Cost-effective solution for most industrial boiler applications.

Enamel-Coated Tubes

Applied where low-temperature corrosion or fouling is critical. Protective coating extends service life in challenging environments.

High-Alloy / ND Materials

ND(09CrCuSb) and other grades for high sulfur and high acid-dew-point environments. Essential for waste-to-energy plants.

Typical Configuration: Tube-side is usually combustion air and gas-side is boiler flue gas. Layout and cleaning method (soot blower / washing) are selected according to dust load and maintenance conditions.

Typical Materials for APH

| Component | Common Materials | Design Focus |

|---|---|---|

| Heat exchange tubes | SA178, SA179, SA192, SA210A1, SA106B, 20#, Q235B | Heat transfer, strength and manufacturability |

| Corrosion-resistant tubes / panels | ND(09CrCuSb), alloy steels as per spec | Low-temperature corrosion / acid dew point areas |

| Casing & support | P195GH, P235GH, P265GH, carbon steels | Structure, expansion and maintenance space |

Why Choose ORL for Boiler Air Preheaters?

We combine boiler pressure-parts experience, material know-how and project communication to support your CFB and industrial boiler upgrades.

Engineering-Driven Design

Air preheater layout, tube pitch and flow arrangement are based on your flue gas data, boiler drawings and cleaning method, not just a catalogue size.

Material & Corrosion Expertise

Experience with ND(09CrCuSb) and enamel-coated tubes for low-temperature corrosion zones in waste-to-energy and biomass boilers.

Controlled Fabrication & NDT

Tube cutting, welding, leak tests and NDT (RT/UT/PT/MT as specified) are performed according to procedures, with full material traceability.

Transparent Project Communication

Project engineers follow your order from drawing review to packing photos, so your engineering and purchasing teams always know the status.

Certified Quality & Manufacturing Strength

Boiler and pressure-vessel manufacturing qualifications, supported by documented material control and inspection records.

Code-based Design & Fabrication

APH and related pressure parts are designed and manufactured under applicable boiler and pressure-vessel codes and internal quality system.

Material Traceability

Each tube bundle and casing is linked with MTCs, identification marks and fabrication records to support future inspection and replacement.

Third-Party Inspection Ready

We cooperate with appointed third-party agencies according to your ITP, including witness of material, welding and final inspection stages.

-scaled.jpg)

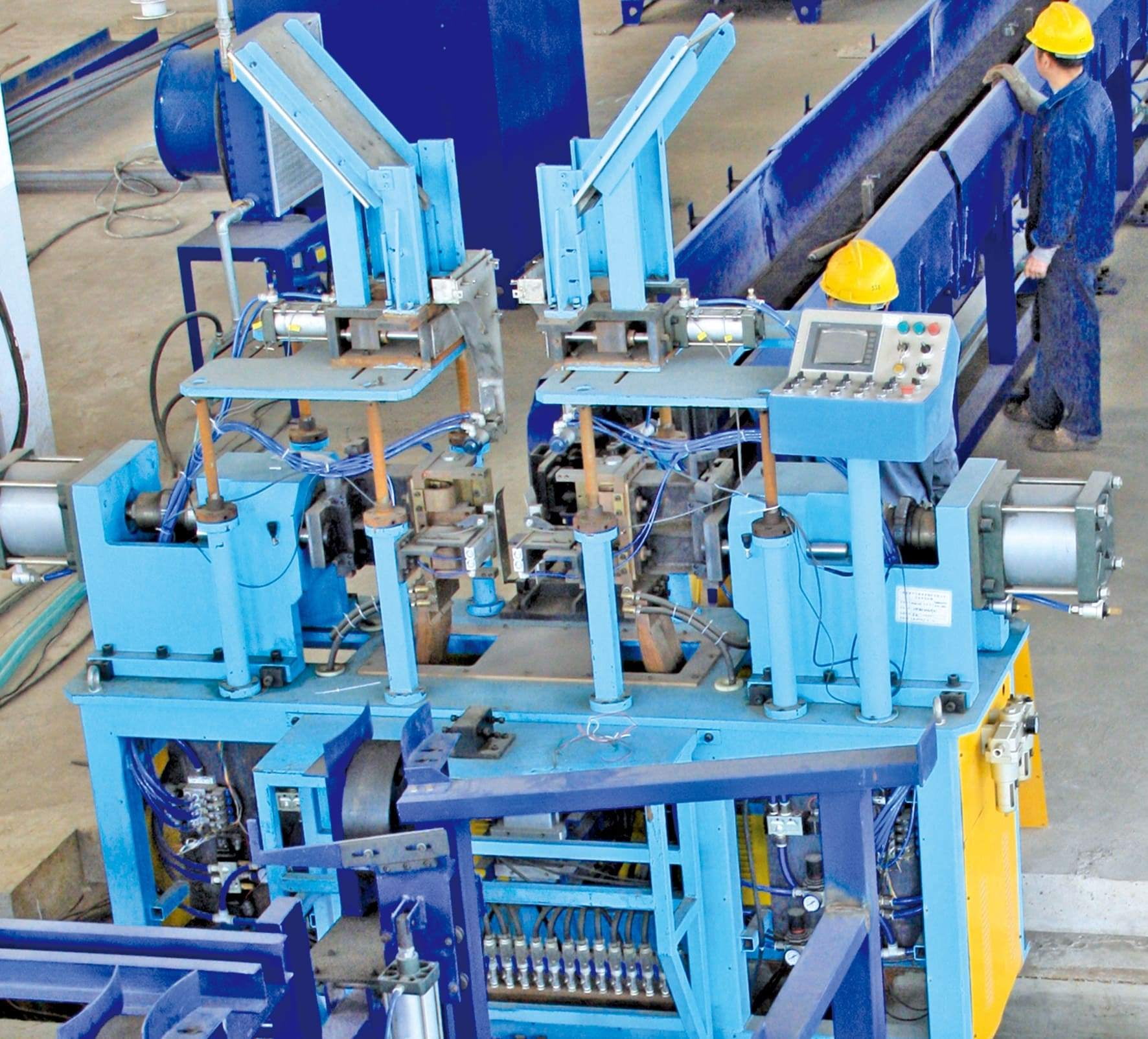

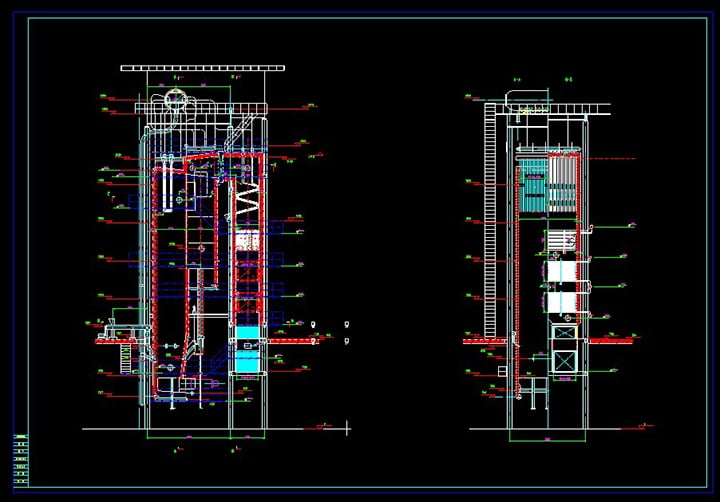

Our Manufacturing Facilities

Dedicated production lines for boiler pressure parts and air preheaters, covering forming, bending, welding, machining, laboratory testing and NDT.

Automatic Plate Machine

Pipe Bending Machine

Submerged Arc Welding

GMAW Welding Line

Chamfering Machine

Testing Laboratory

.jpg)

NDT Radiography

Assembly Workshop

From Design to Delivery – Full Process Control

A clear workflow that your project and engineering teams can easily follow.

Engineering & Layout Review

We start from your boiler GA drawings, flue-gas data and combustion-air system to define the APH position, connections and cleaning method.

- Check flue gas temperature, flow and dust / corrosive components

- Confirm desired air outlet temperature and allowable pressure drop

- Review maintenance access and replacement routes

Material Selection & Procurement

Tube, header and casing materials are selected according to your specification and the actual flue gas environment.

- Standard carbon-steel tubes for normal conditions

- ND(09CrCuSb) or other special grades for low-temperature corrosion areas

- MTC review, identification and storage with traceability

Tube Bundle Fabrication

Tube cutting, bending, welding and bundle assembly follow controlled procedures to match your drawing and interface dimensions.

- Tube pitch and bundle arrangement as per thermal design

- Welding procedures and qualified welders for tube-to-tube-sheet joints

- Internal cleaning and protection before assembly

Quality Inspection & NDT

Inspection scope is defined in the ITP according to project requirements.

- Visual and dimensional inspection for critical welds and interfaces

- NDT such as RT, UT, PT and MT for specified weld joints

- Leak and pressure tests where applicable

Surface Protection & Shipping

Before shipment, air preheater modules are protected and packed for overseas transport and site handling.

- External painting or coating according to your paint system

- Blocking and bracing for sea transport, with lifting points marked

- Packing list and photo documentation for each shipment

How an Air Preheater Improves Your Boiler System

The air preheater is installed in the flue gas path downstream of the boiler. Hot flue gas transfers heat to the incoming combustion air, which then enters burners or furnace with a higher temperature.

Performance Benefits

- Helps fuel ignite more easily and burn more completely

- Lowers flue gas outlet temperature and reduces wasted heat

Application Value

- Supports firing of high-moisture biomass and waste-derived fuels

- Works together with economizer and other heat-recovery equipment

Bottom Line: Compared with a boiler without air preheater, properly designed APH can noticeably reduce fuel consumption over the long term and improve the stability of the combustion process.

Common APH Problems & How We Address Them

Low-Temperature Corrosion

Cause: Flue gas temperature drops below acid dew point, causing sulfuric acid condensation on tube surfaces

ORL Solution: ND(09CrCuSb) tubes in cold-end zones, proper minimum temperature control, regular inspection openings

Ash Fouling & Plugging

Cause: High dust loading in flue gas, sticky ash deposits on tube surfaces reducing heat transfer

ORL Solution: Optimized tube pitch for cleanability, soot blower provisions, water washing access where applicable

Air Leakage

Cause: Thermal expansion mismatches, gasket degradation, poor joint sealing

ORL Solution: Expansion joint design, high-temperature gasket selection, leak testing before shipment

Inadequate Heat Transfer

Cause: Wrong tube size/pitch, undersized heat transfer area, poor flow distribution

ORL Solution: Thermal calculation based on actual flue gas data, not catalog assumptions; CFD analysis for complex cases

Critical Insight: Most APH failures are preventable through proper material selection for the flue gas environment and adequate cleaning provisions. "One-size-fits-all" catalog solutions often fail because they don't account for your specific fuel, ash characteristics, and operating pattern.

Key Parameters for APH Selection

Operating Data Needed

-

Boiler Information: Type, steam capacity / heat duty and operation hours

-

Fuel Characteristics: Fuel type and composition (sulfur, chlorine, ash content)

-

Flue Gas Conditions: Temperature and flow rate at APH inlet

Design Requirements

-

Target Performance: Required air outlet temperature and current air temperature

-

Maintenance Strategy: Dust loading and allowed cleaning method (soot blower, water washing)

-

Site Constraints: Available installation space and connection interface

Professional Tip: When you send an inquiry, sharing at least part of the data above helps our engineers quickly judge the APH size, material and layout options that fit your project. Even partial information (e.g., "130 t/h CFB boiler burning anthracite coal, flue gas at APH inlet ~350°C") is a good starting point – our engineers can ask focused questions afterwards.

Air Preheater FAQ

Practical questions from boiler owners, EPC contractors and engineering teams – in one place.

Q: What information do you need to prepare an APH quotation?

A: Please provide as much of the following as you have:

- • Boiler type, steam capacity or heat duty, fuel type

- • Flue gas temperature and approximate flow at APH position

- • Target air outlet temperature and current air temperature

- • Basic layout drawing or sketch showing available space

- • Any specified materials, codes or client requirements

Even if not all data are available, sharing partial information is a good starting point – our engineers can ask focused questions afterwards.

Q: Can you replace an existing air preheater from another OEM?

Q: How do you control corrosion risk at low flue gas temperatures?

A: Corrosion risk is related to fuel sulfur/chlorine content, flue gas temperature profile and condensation of acid components. We can combine measures such as:

- • Using ND(09CrCuSb) or other special grades in critical zones

- • Enamel-coated tubes where appropriate

- • Defining a safe minimum flue gas outlet temperature

- • Providing inspection openings for regular checking of sensitive areas

Q: What inspection and testing documents will we receive?

A: Documentation is prepared according to your order and may include:

- • MTCs for major materials

- • WPS / PQR and welder qualification records where applicable

- • Dimensional inspection reports

- • NDT reports (RT / UT / PT / MT as specified)

- • Pressure or leak test records if required by the design

Q: How is the typical project process when working with ORL?

A: For APH projects the common workflow is:

- • Technical communication and data collection

- • Preliminary proposal and budget quotation

- • Final design and documents after order confirmation

- • Material procurement, fabrication and inspection

- • Packing, shipping and after-sales technical support

Q: What's the difference between shell & tube APH and rotary APH?

Ready to Discuss Your Air Preheater Project?

Share your boiler data and targets with us. Our team will review the information and get back to you with engineering suggestions and a quotation.

Information to Provide:

- Boiler type, capacity and main fuel

- Flue gas temperature at APH position

- Required air outlet temperature

- Any special material or code requirements

Request Air Preheater Quote

Please leave your contact information and basic requirements. We will reply as soon as possible.