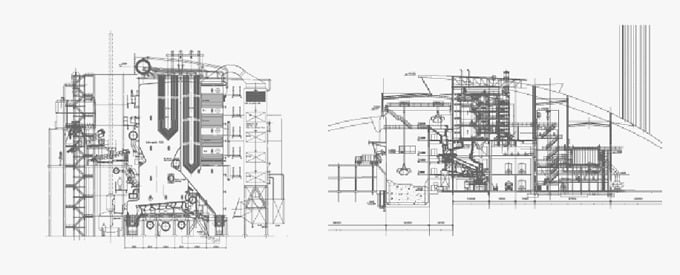

Waste Incineration Boiler Series

Complete waste-to-energy boiler solutions for municipal solid waste, industrial waste and hazardous waste. ORL designs and manufactures corner tube, CFB and rotary kiln type waste incineration boilers with stable performance and reliable flue gas treatment interfaces.

Waste Incineration Boiler Solutions

Practical answers to the most common questions from EPC contractors, plant owners and municipal waste-to-energy operators.

What types of waste incineration boilers can ORL supply?

ORL provides complete boiler islands for different waste handling technologies. We match boiler design to your furnace and waste characteristics to ensure stable combustion and long-term operation.

- • Rotary kiln + waste heat boiler for hazardous and medical waste

- • CFB (circulating fluidized bed) waste incineration boilers

- • Mechanical grate municipal solid waste (MSW) boilers

- • Customized solutions for industrial solid waste and sludge

What is the typical capacity range of your waste incineration boilers?

ORL has experience in the design and manufacture of waste incineration boiler components and complete units up to 500 t/d for municipal waste. Capacity and configuration are engineered based on your incoming waste volume and energy recovery targets.

- • Single-line or multi-line waste boiler islands

- • Integration with steam turbine or district heating network

- • Flexible layout to fit new plants or retrofit projects

How is steam side safety and reliability ensured?

Waste incineration boilers operate under highly corrosive and variable conditions. ORL designs pressure parts and support structures to maintain safe operation over the full service life.

- • Optimized circulation design for stable water/steam flow

- • Proper drum sizing and separation internals for dry steam

- • Proven welding procedures and 100% critical weld inspection

- • Online access for inspection, cleaning and maintenance

How do you handle high flue gas corrosion and fouling?

Waste flue gas often contains high levels of chlorine, sulphur and particulates. ORL combines proper material selection with proven surface protection and cleaning methods.

- • Alloy steel and cladding in high-risk zones

- • Optimized flue gas velocity to reduce erosion

- • Sootblowers and rapping systems for heating surfaces

- • Interfaces prepared for upstream SNCR/SCR and downstream gas cleaning systems

Can ORL support boiler design integration with existing WtE plants?

Yes. Our engineering team is familiar with international waste-to-energy projects and cooperates with EPC contractors and design institutes to match local standards and existing equipment.

- • Adaptation to client furnace and flue gas system

- • Connection to existing steam headers and turbines

- • Layout design to fit limited plant space

What information is required for a detailed proposal?

To prepare an engineering-based proposal, our team will review your waste, energy and plant data in detail and then communicate technical parameters with you one-to-one.

- • Waste type, composition and lower heating value (LHV)

- • Required steam parameters and energy recovery mode

- • Local emission limits and environmental regulations

- • New plant or retrofit, available plot plan and layout constraints

Design Highlights for Waste Incineration Boilers

ORL participated in waste incineration power plant projects early in China and has supplied pressure parts and boiler islands for many international waste-to-energy projects.

Modular Boiler Structure

Furnace, convection pass and economizer surfaces are arranged in compact modules with rational gas flow and easy transportation. This reduces on-site welding and shortens installation cycles while keeping maintenance access clear.

Optimized Heat Recovery

Heating surfaces are configured for stable steam generation under variable waste calorific value. Proper surface temperature control minimizes corrosion risk while maximizing energy recovery for power and heat supply.

Safe & Reliable Operation

Design complies with relevant boiler and pressure vessel codes. Each project includes complete drawings and documentation, and third-party inspection can be arranged according to customer requirements.

Get Your Waste Incineration Boiler Proposal

Tell us about your waste-to-energy project. Our engineering team will review your data and contact you with technical suggestions and a customized solution.

Talk to ORL Engineering

Please share basic project information first. Detailed technical parameters and guarantees will be discussed directly with our sales and engineering managers according to your needs.

Helpful details to include:

- • Waste type and daily tonnage

- • Target steam parameters and power/heat output

- • New plant or retrofit & expected start-up time frame

- • Local codes / standards to be considered