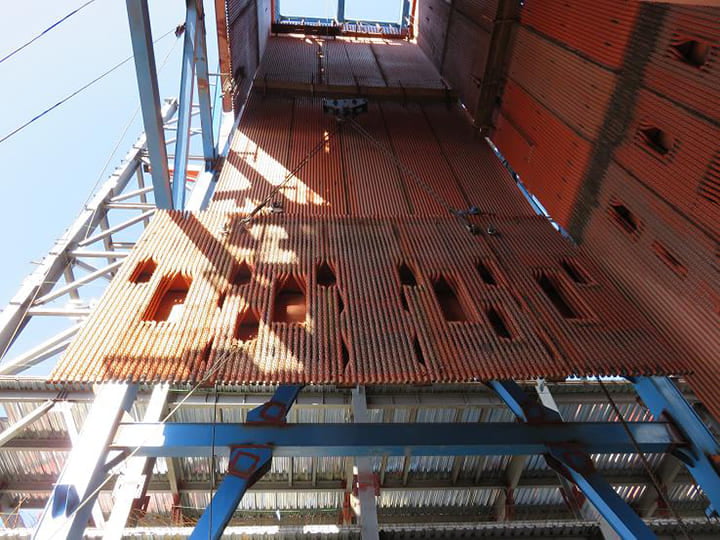

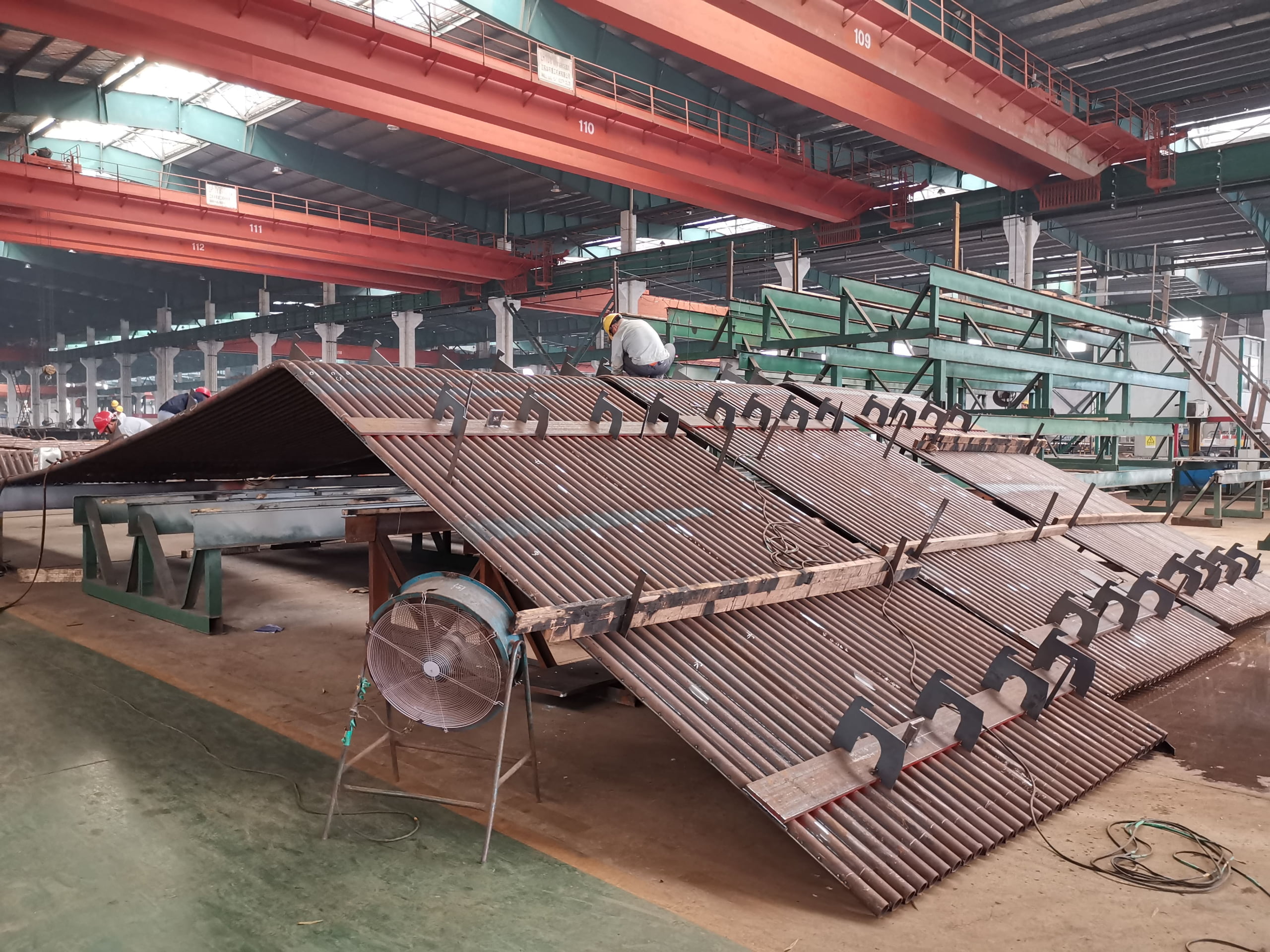

Boiler Water Wall Panels

Membrane water wall panels forming a gas-tight furnace enclosure for CFB, biomass, waste-to-energy and industrial boilers – engineered for high heat absorption, low air leakage and long service life.

Water Wall Panel Solutions

Clear answers to the key questions boiler owners, maintenance teams and EPC contractors ask before replacing or adding boiler water wall panels.

What is a boiler water wall panel?

A boiler water wall panel is a set of closely spaced tubes welded together, usually with membrane bars between the tubes, to form gas-tight walls around the furnace. These panels absorb radiant and convective heat from the flame, protect the casing and refractory, and form the structural enclosure of the combustion chamber.

Which tube materials can you supply?

ORL manufactures water wall panels using a full range of carbon and alloy steels. Material grade is matched to your design pressure, temperature and fuel conditions.

- SA-210 A1 – standard carbon steel for many furnace walls

- T11 / T22 – low-alloy Cr-Mo steels for higher temperature zones

- T91 – 9Cr martensitic material for high-pressure, high-temperature boilers

- Other grades available on request to meet project standards

What information do you need to prepare a quotation?

With complete technical data, we can design the panel layout, select materials and reply with a clear, comparable offer.

- • Boiler type and fuel (CFB, biomass, waste-to-energy, waste heat, etc.)

- • Design pressure & temperature of water / steam circuit

- • Tube OD, wall thickness and tube spacing

- • Panel height, width and quantity (side / front / rear / roof / floor)

- • Required design codes (ASME, GB, EN, etc.) and material grades

- • New boiler or replacement / retrofit project

How long does water wall panel replacement normally take?

Actual outage time depends on boiler size, access and on-site crew capacity. Our pre-fabricated, installation-ready panels are designed to shorten shutdowns:

What causes water wall tube failures and how do you address them?

Typical failure mechanisms include overheating, corrosion, erosion and thermal fatigue. When replacing panels, ORL can adjust design and material to address the root causes.

What quality standards and documentation do you provide?

All water wall panels are manufactured under a certified quality system with full traceability and inspection records.

Technical Specifications

Designed to fit modern power and industrial boilers, with flexible material, size and code options to match your project requirements.

Materials

- SA-210 A1 carbon steel

- T11 (1.25Cr–0.5Mo) low-alloy steel

- T22 (2.25Cr–1Mo) low-alloy steel

- T91 (9Cr–1Mo–V–Nb) martensitic steel

- Other grades per ASME / GB / EN on request

Dimensions

- Tube OD: typically 32–76 mm

- Tube wall thickness: 3–8 mm

- Panel height: up to approx. 15 m

- Panel width: up to approx. 8 m

- Custom layouts for side, front, rear, roof and floor walls

Operating Range

- Design pressure: up to approx. 18.5 MPa

- Design temperature: up to approx. 580°C

- Design life: typically 25+ years with proper operation

- Design codes: ASME / GB / EN (project-based)

- NDE: 100% inspection according to specification

Get Your Water Wall Panel Quote

Share your boiler data and drawings with our engineering team. We will review your requirements and reply with a technical proposal and quotation within 24 hours (working days).

Why Choose ORL Power?

ASME & GB Certified Manufacturing

Water wall panels produced to international boiler codes with full material and NDE documentation.

On-Time Delivery for Outages

Production planning based on your shutdown window to minimize downtime risk.

Engineering-Driven Support

In-house boiler specialists to review your drawings, failure history and optimization ideas.