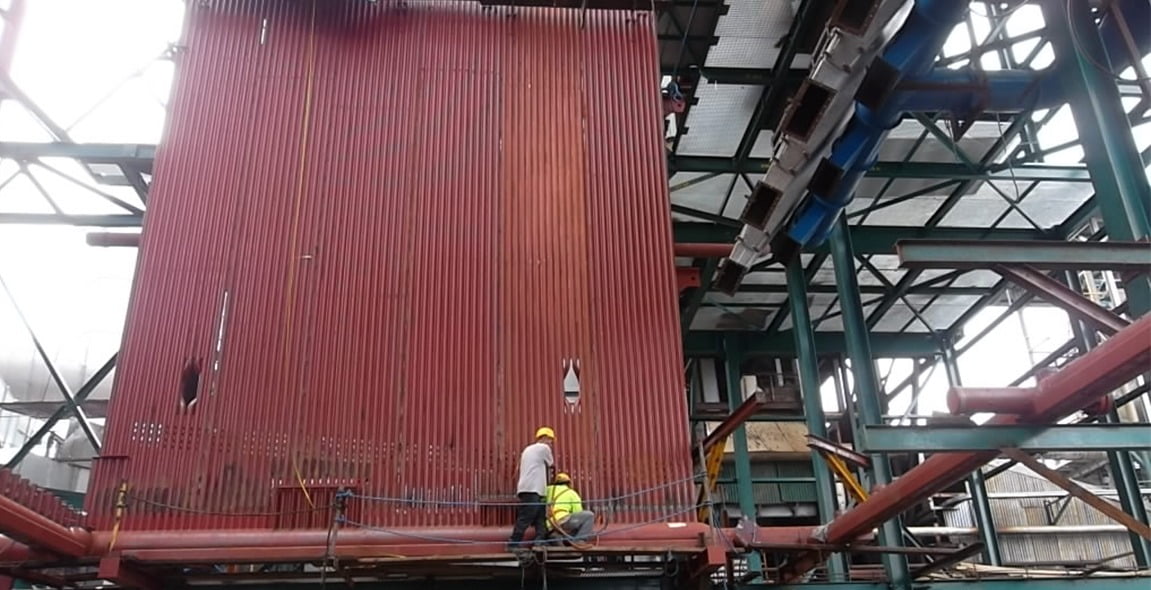

Biomass Boiler for Sugar Mill – 2 Sets (200 t/h) (Philippines, 2015-2016)

ASME-compliant biomass boiler twin units with phased installation and synchronized commissioning for enhanced sugar mill cogeneration capacity.

Project Gallery

Detailed views of the twin-unit biomass boiler project

Project Snapshot

Core project information at a glance

Project Information

| Field | Value |

|---|---|

| Product | Biomass Boiler for Sugar Mill – 2 Sets (200 t/h each) |

| Design Code | ASME |

| Country / Region | Philippines |

| Year | 2015, 2016 |

| Industry / Application | Sugar Mill Cogeneration |

| Scope Type | Twin-Unit Boiler System Supply |

Client Core Needs

Key requirements for capacity expansion

Doubled Capacity Requirement

Expand cogeneration capacity to support increased sugar production

Phased Implementation

Sequential delivery across 2015-2016 to minimize operational disruption

Consistent Quality Standards

Identical ASME-compliant units for simplified operation and maintenance

ORL Solution

Comprehensive twin-unit delivery strategy

Standardized Twin-Unit Design

Identical ASME-compliant specifications for both units

Synchronized Manufacturing Schedule

Coordinated production for sequential delivery

Bagasse-Optimized Combustion System

Custom design for sugar cane residue firing

Phased Installation Management

First unit (2015), second unit (2016) with minimal downtime

Unified Quality Control Protocol

Consistent inspection and testing across both units

Complete Documentation Package

Separate acceptance records for each unit

Quality & Documentation Package

Comprehensive quality assurance for twin-unit projects

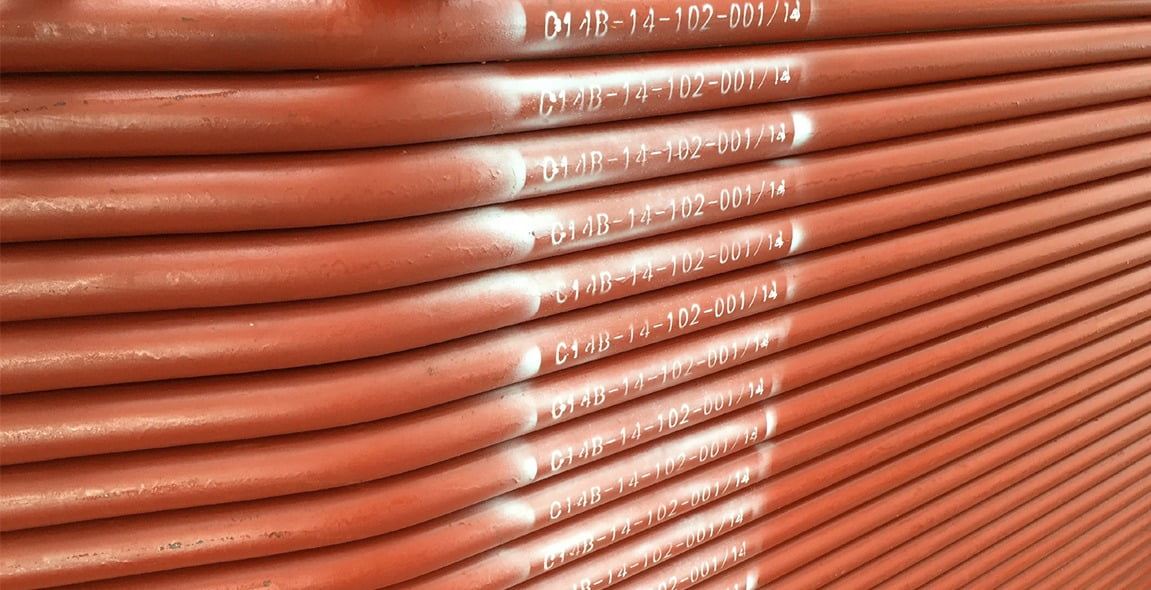

Material Certificate / EN 10204 3.1

(as required)

Full Traceability

(heat no. tracking)

Dimensional Inspection Report

Comprehensive measurements

Hydro Test Record

(if applicable)

ASME Compliance Verification

Code compliance documentation

ITP / QCP Support

(if required)

Third-party Inspection Support

(if required)

Separate Documentation Sets

Individual packages for each unit

Related Information

Explore related products and solutions

Related Products

Get Custom Quotation – Send Your Requirements

Quotation is based on product specification, code requirements and acceptance documentation needs

Required Information for RFQ

Drawing / product specification

Design code (ASME/EN/GB)

Operation conditions (pressure/temperature)

Required documentation & inspection

Quantity & delivery time